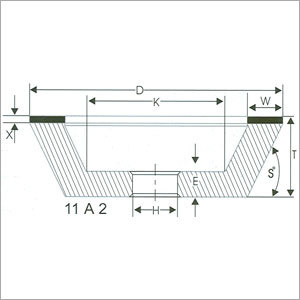

Taper Cup Diamond in Rims

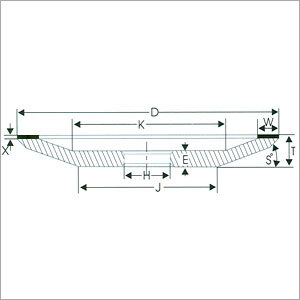

Taper Cup Diamond in Rims Specification

- Size

- Available in various standard and custom sizes

- Bonding Agent

- Metallic

- Product Type

- Taper Cup Diamond Wheel (in Rims)

- Texture

- Fine or Medium depending on grit

- Shape

- Cup, Tapered

- Grain Size

- Assorted (by requirement)

- Bond Type

- Metal Bond

- Abrasive Grit Size

- 80 to 400 (other grits on request)

- Hole Size

- 20mm, 31.75mm, Customized

- Width

- Customize as per application

- Abrasive

- Industrial Diamond

- Application

- Grinding, precision tool sharpening, carbide, glass, ceramics

- Abrasive Concentration

- 75%, Custom as per need

- Harness

- High (suitable for hard materials)

Taper Cup Diamond in Rims Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 200 Pieces Per Day

- Delivery Time

- 12 TO 15 DAYS Days

- Packaging Details

- IN FOUR LAYERS. 1. IN BOX WITH BUBBLE 2. THERMOCOL SHEET 3. CARTOON BOX AND LAST 4. TRANSPARENT PVC ROLL PACKING.

- Main Export Market(s)

- North America, Africa

- Main Domestic Market

- All India

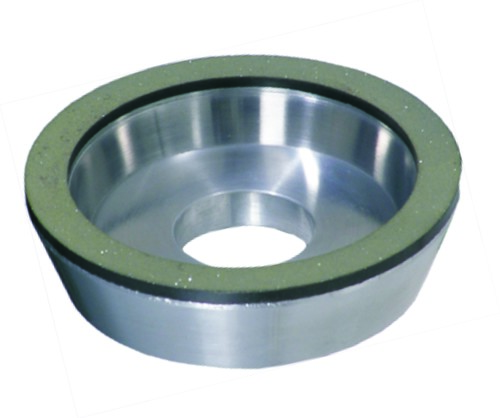

About Taper Cup Diamond in Rims

Our expertise in this domain enables us to manufacture, export and supply a wide gamut of high quality Taper Cup Diamond in Rims. The offered tool is manufactured at our highly advanced production unit by utilizing quality approved raw materials and modern technology under the stern guidance of skilled technocrats in adherence with set market quality standards. Our provided tool is used for grinding several ceramics and tungsten carbide tools. Furthermore, this Taper Cup Diamond in Rims can be purchased by our clients from us at industry leading prices.

Features:

-

Elevated durability

-

High tensile strength

-

Easy to install

-

Light weight

Precision Grinding With Custom Solutions

Our taper cup diamond rims deliver superior performance for grinding and precision tool sharpening across a variety of hard materials. The flexibility in size, grain, and bond type enables professionals to achieve consistent and accurate results no matter the application. Custom solutions are available to ensure optimal outcomes for specialized needs.

Versatile Applications Across Industries

Whether used in toolrooms, manufacturing facilities, or workshops, these diamond cup rims are suitable for carbide, glass, and ceramic operations. Their robust construction and adjustable abrasive concentration make them particularly effective in industries demanding high-precision finishing.

Quality Manufacturing and Export Expertise

As an established Indian exporter, manufacturer, and supplier, we maintain stringent quality standards throughout our fabrication process. Every wheel can be adapted to meet global performance expectations, ensuring you receive a product that meets your specific requirements for durability and efficiency.

FAQs of Taper Cup Diamond in Rims:

Q: How are Taper Cup Diamond rims customized for specific applications?

A: Taper Cup Diamond rims are tailored by adjusting parameters such as width, grain size, abrasive concentration, hole size, and grit texture according to your application requirementsensuring optimal performance for unique grinding or sharpening tasks.Q: What materials can be processed using these taper cup diamond wheels?

A: These wheels are engineered for grinding and sharpening hard materials, including carbide, glass, and ceramics, making them suitable for diverse industrial and toolroom applications where precise finishing is essential.Q: When should I choose a fine or medium texture for my diamond rim?

A: Select a fine texture for intricate, high-precision jobs demanding smooth finishes. Opt for a medium texture when faster material removal and robust performance are desired, or as dictated by the grit size and application.Q: Where can these diamond rims be used effectively?

A: They are ideal for use in toolrooms, manufacturing plants, and workshops engaged in grinding, sharpening, or surface finishing of hard materials. Their adaptability makes them suitable for both industrial and specialized operations.Q: What is the process behind the manufacturing of these diamond grinding wheels?

A: These wheels are produced using advanced metal bonding techniques, embedding industrial diamond abrasives at the required concentration. Each parametersuch as size, grit, and hole diameteris customized per order to ensure high durability and precision.Q: How do these wheels benefit my grinding or sharpening operations?

A: With high hardness, customizable features, and the ability to maintain sharpness, these wheels increase efficiency, reduce downtime, and deliver consistent, precise results, even on challenging materials.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Resin Bonded Diamond Wheels Category

Resin Bond CBN Wheel

Price 1000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Size : 100 DIA

Shape : ROUND

Thickness : 3MM & 6MM Millimeter (mm)

Product Type : INDUSTRIAL DIAMOND CUP WHEEL

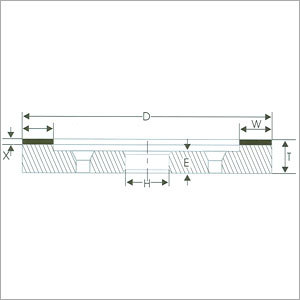

Plain Cup Diamond in Rim with Countersunk Bolt

Minimum Order Quantity : 1 Piece

Size : Standard and Custom sizes available

Shape : Round Cup

Thickness : 10 mm to 20 mm (customizable)

Product Type : Plain Cup Diamond in Rim with Countersunk Bolt

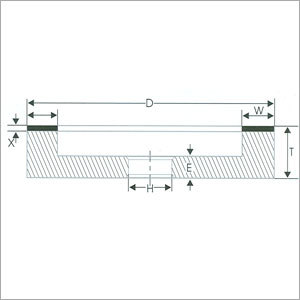

Plain Cup Diamond in Rim

Minimum Order Quantity : 1 Piece

Size : Customizable

Shape : Cup

Thickness : 5 mm to 30 mm

Product Type : Plain Cup Diamond in Rim

Rims Dish Diamonds

Price 900 INR / Piece

Minimum Order Quantity : 1 Piece

Size : 50mm to 200mm

Shape : ROUND

Thickness : T1.2MM TO 100MM Millimeter (mm)

Product Type : RESIN BOND DIAMOND/CBN WHEEL

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS