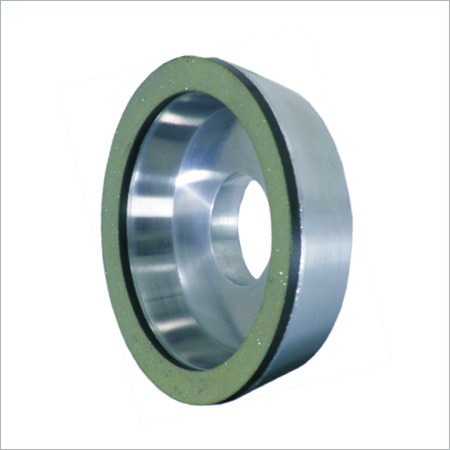

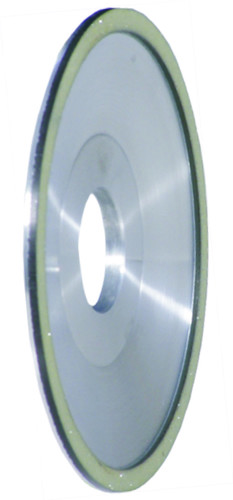

CBN wheels

CBN wheels Specification

- Harness

- High Hardness

- Grain Size

- 80 to 400 mesh

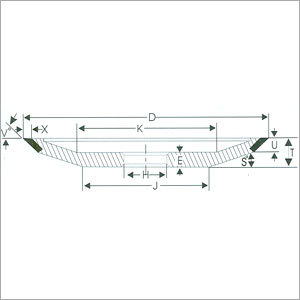

- Depth of Working Layer

- 3 mm to 10 mm

- Width of Working Layer

- 3 mm to 20 mm

- RPM

- Up to 3000 RPM

- Texture

- Fine to Coarse

- Abrasive Grit Size

- D126, D91, D151, D181, D251, D301

- Size

- Customized as per requirement

- Abrasive

- Cubic Boron Nitride (CBN)

- Thickness

- 5 mm to 30 mm

- Bond Type

- Resin, Metal, Electroplated

- Width

- Varies (Typically 3 mm to 50 mm)

- Product Type

- CBN wheels

- Bonding Agent

- Resin, Metal, Electroplated

- Application

- Grinding, Sharpening, Precision Machining

- Shape

- Flat, Cup, Dish, Profile

- Wheel Size

- Diameter ranges from 25 mm to 400 mm

- Hole Size

- 10 mm to 100 mm

- Abrasive Concentration

- 75%, 100%, 125%

- Coolant Compatibility

- Oil, Water, Synthetic

- Bond Strength

- High (Metal Bond); Moderate (Resin Bond)

- Safety Standard

- Complies with ISO 6104

- Life Expectancy

- Long-lasting compared to conventional grinding wheels

- Manufacturing Tolerance

- 0.02 mm

- Precision Level

- Suitable for ultra-precision grinding

- Maximum Operating Speed

- Up to 35 m/s

- Workpiece Materials

- High-speed steel, cast iron, tool steel, hardened alloy steel

- Heat Resistance

- Excellent for continuous operation

- Surface Finish

- Superior finish, low roughness Ra < 0.15 m

- Wheel Balancing

- Factory balanced to ISO standards

CBN wheels Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID), Cheque

- Supply Ability

- 200 Pieces Per Day

- Delivery Time

- 12 Days

About CBN wheels

Precision Engineering for Demanding Applications

CBN wheels are manufactured with tight tolerances of 0.02 mm and offer various shapes such as flat, cup, dish, and profile, ensuring exceptional accuracy in critical machining tasks. Their ultra-fine abrasive composition delivers a superior surface finish with roughness values as low as Ra < 0.15 m, making them suitable for industries needing high-precision results.

Exceptional Safety and Longevity

Designed for continuous industrial use, these wheels are factory balanced according to ISO standards and maintain integrity up to 3000 RPM. Their high hardness and resistance to heat translate to prolonged tool life, reducing replacements and enhancing overall productivity for manufacturers and suppliers.

FAQs of CBN wheels:

Q: How can I select the right CBN wheel for my application?

A: To choose a suitable CBN wheel, consider the workpiece material (such as high-speed steel or hardened alloy steel), required surface finish, application type (grinding, sharpening, precision machining), and compatible bond type (resin, metal, electroplated). Customization in grain size, wheel shape, and dimensions is available to match specific machining needs.Q: What are the advantages of using CBN wheels over conventional grinding wheels?

A: CBN wheels deliver a longer service life, higher precision, and superior surface finish, thanks to their heat-resistant properties and robust bond strength. They minimize downtime due to less frequent wheel changes and enable efficient grinding of hard materials, enhancing productivity in both small-scale and high-volume operations.Q: When should coolant be used with CBN wheels?

A: Coolant should be employed during operations to reduce heat buildup, prolong wheel life, and ensure a consistent, high-quality finish. These wheels are compatible with oil, water, and synthetic coolants, making them versatile for various industrial environments.Q: Where are CBN wheels typically used?

A: CBN wheels are widely utilized in tool manufacturing, automotive, aerospace, and heavy machinery sectors. They are ideal for applications demanding ultra-precision grinding, such as sharpening tools, precision machining components, and working with hardened steels and alloys.Q: What is the manufacturing process for customizing CBN wheels?

A: Our manufacturing process involves selecting the appropriate abrasive grit size (ranging D91 to D301), concentration (75%125%), and bonding agent. Wheels are engineered according to customized dimensions for diameter, thickness, hole size, and layer depth. Quality control ensures adherence to ISO 6104 safety standards and customer specifications.Q: How does the balancing of CBN wheels benefit industrial operations?

A: Factory balancing to ISO standards ensures these wheels operate with minimal vibration, resulting in smoother finishes, improved safety, and reduced wear on machinery. This translates into reliable, consistent performance throughout the wheels extended lifespan.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Resin Bonded Diamond Wheels Category

Resin Bonded Diamond Wheels

Price 800 INR / Piece

Minimum Order Quantity : 1 Piece

Thickness : 1.5mm and 6mm Millimeter (mm)

Size : 100 DIA

Abrasive : RESIN BOND

Abrasive Concentration : C50/C75/C100

Diamond grinding wheels

Price 800 INR / Piece

Minimum Order Quantity : 1 Piece

Thickness : 6mm Millimeter (mm)

Size : Dia 150, W 6mm, H 31.75, D126, C100x1.5

Abrasive : Resing Bond

Abrasive Concentration : C100

Dish Diamond in Corner

Minimum Order Quantity : 1 Piece

Thickness : 5 mm

Size : 4 inch

Abrasive : Industrial Diamond

Abrasive Concentration : Standard

Resin Bond Diamond Radius Wheel

Minimum Order Quantity : 1 Piece

Thickness : 8 mm to 50 mm (varies)

Size : Available in multiple diameters

Abrasive : Synthetic Diamond

Abrasive Concentration : Standard or customized (typically 75%100%)

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS