Straight Diamond Periphery

Straight Diamond Periphery Specification

- Abrasive Concentration

- Standard and custom concentrations available

- Application

- Glass, Ceramic, Gemstone, Carbide, and Tool Grinding

- Texture

- Fine/Coarse as per grit size

- Bond Type

- Resin, Metal, Vitrified (as per requirement)

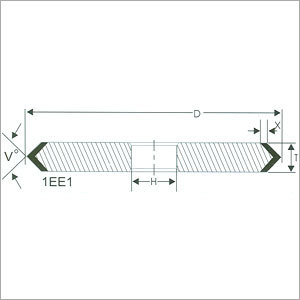

- Shape

- Straight

- Wheel Size

- Customizable diameter

- Thickness

- Customizable

- Abrasive Grit Size

- 80 to 400 mesh

- Harness

- High (suitable for hard materials)

- Abrasive

- Industrial Diamond

- Hole Size

- Custom bore available

- Product Type

- Straight Diamond Periphery Wheel

- RPM

- Up to 4000 rpm depending on specification

- Size

- As per customer requirement

- Bonding Agent

- Resin, Metal, or Vitrified based on application

- Width

- Customizable

Straight Diamond Periphery Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Letter of Credit at Sight (Sight L/C), Cash in Advance (CID)

- Supply Ability

- 200 Pieces Per Day

- Delivery Time

- 12 TO 15 DAYS Days

- Packaging Details

- IN FOUR LAYERS. 1. IN BOX WITH BUBBLE 2. THERMOCOL SHEET 3. CARTOON BOX AND LAST 4. TRANSPARENT PVC ROLL PACKING.

- Main Domestic Market

- All India

About Straight Diamond Periphery

We are encouraged by our treasured customers to manufacture, export and supply the finest quality gamut of Straight Diamond Periphery. The provided tool is used for grinding purpose. This tool is accurately manufactured at our well-equipped production unit using contemporary technology and supreme quality raw materials under the perfect observation of adroit technocrats in compliance with set market quality standards. Along with this, we assure our clients the on-time delivery of this Straight Diamond Periphery at negotiable prices.

Features:

-

Excellent durability

-

Resistant to abrasion

-

Lightweight

-

Precisely designed

Engineered for Versatility and Precision

Designed to deliver consistent performance across demanding applications, our straight diamond periphery wheels cater to a wide spectrum of industries requiring the abrasion of glass, ceramics, gemstones, carbide, and tooling materials. Precision customization ensures you get the optimum configuration for your process.

Customization to Match Every Requirement

With tailored dimensions, bore sizes, abrasive concentrations, and grit textures, each wheel is manufactured to your exact specifications. Our advanced production process allows for flexible adaptation, ensuring each order matches the rigidity and performance expected for high-hardness material grinding.

Multiple Bonding Options for Enhanced Performance

Select from resin, metal, or vitrified bonds based on operating conditions and material properties. This choice allows for effective grinding solutions whether the application demands rapid stock removal, fine surface finish, or extended wheel life.

FAQs of Straight Diamond Periphery:

Q: How are Straight Diamond Periphery Wheels customized to specific requirements?

A: These wheels can be produced in customizable widths, diameters, thicknesses, and bore sizes, as well as with specific abrasive concentrations and grit sizes. You simply provide the required dimensions and application details, and the manufacturer will tailor the wheel to meet your exact needs.Q: What materials are suitable for grinding with these wheels?

A: Straight Diamond Periphery Wheels are designed for use on hard materials such as glass, ceramics, gemstones, and carbide. Their high harness and industrial diamond abrasive prolong wheel life and efficiency, making them ideal for precision grinding.Q: When should I choose resin, metal, or vitrified bond types?

A: The choice of bond depends on the application: resin bonds offer good cutting performance and a fine finish, metal bonds provide long-lasting durability for demanding jobs, and vitrified bonds are best for high-precision grinding requiring thermal stability. The manufacturer can help you select the best bond for your needs.Q: Where are these diamond wheels manufactured and exported from?

A: These wheels are manufactured in India and supplied to domestic and international markets. The manufacturer is equipped to handle export orders and follows quality standards to ensure reliable global delivery.Q: What is the typical process for ordering and receiving a custom diamond wheel?

A: After you communicate your specifications, the manufacturer consults on selection, prepares a drawing if required, and begins production. Quality checks are performed before dispatch. Delivery timelines depend on complexity and order size, and shipping is arranged globally as needed.Q: How do I use these wheels for optimal grinding performance?

A: To achieve the best results, select the correct bond, grit size, and wheel specifications according to your material and application. Install the wheel securely, ensure appropriate coolant use if needed, and operate within recommended RPMs (up to 4000 rpm, as specified).Q: What are the key benefits of using customizable Straight Diamond Periphery Wheels?

A: Benefits include precision grinding, extended wheel life, compatibility with hard materials, flexibility in specification, and consistent results across different applications. Customization also helps maximize productivity and minimize material wastage.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Resin Bonded Diamond Wheels Category

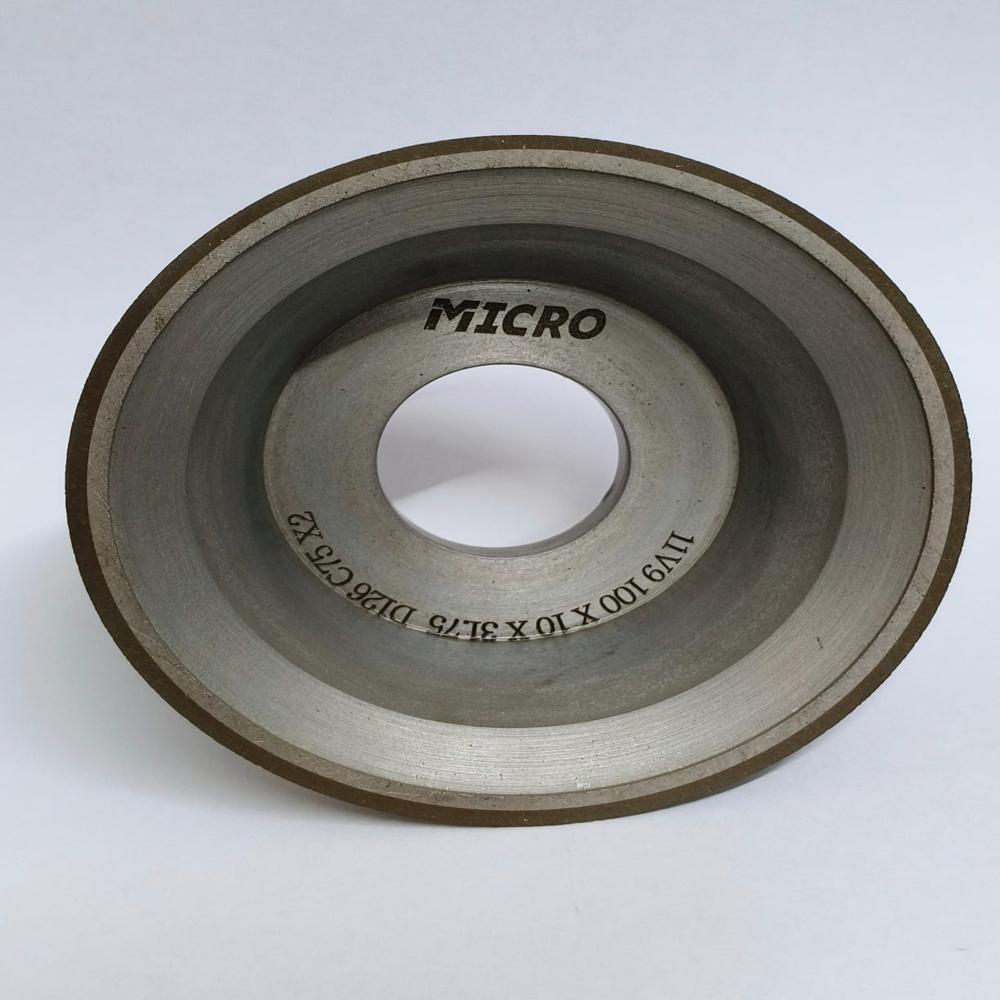

11V9 Diamond Cup Wheel

Price 2000.0 INR / Kilograms

Minimum Order Quantity : 1 Kilograms

Application : carbide grinding/HSS GRINDING

Bond Type : RESIN BOND

Shape : ROUND

Abrasive Concentration : C50/C75/C100

Diamond wheels & CBN Wheels

Price 1000 INR / Piece

Minimum Order Quantity : 1 Piece

Application : carbide grinding

Bond Type : resin bond

Shape : round

Abrasive Concentration : C50/C75/C100

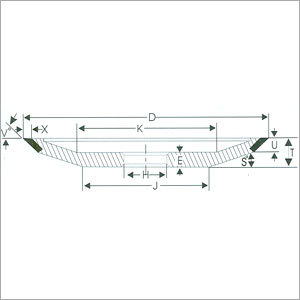

Dish Diamond in Corner

Minimum Order Quantity : 1 Piece

Application : Grinding, Precise Edge Polishing, Tool Sharpening

Bond Type : Resin Bonded

Shape : Dish (in Corner)

Abrasive Concentration : Standard

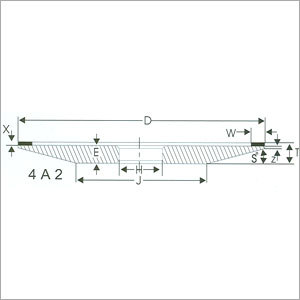

Dish Diamond Rim

Minimum Order Quantity : 1 Piece

Application : Tool Room Grinding, Precision Grinding, Carbide Tools

Bond Type : Resin Bond

Shape : Dish

Abrasive Concentration : 100%

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS