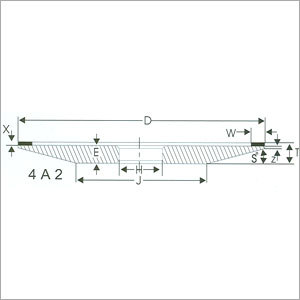

Dish Diamond Rim

Dish Diamond Rim Specification

- Product Type

- Diamond Dish Grinding Wheel

- Abrasive

- Synthetic Diamond

- RPM

- 3200

- Bond Type

- Resin Bond

- Hole Size

- 31.75 mm

- Abrasive Grit Size

- #120

- Width of Working Layer

- 6 mm

- Depth of Working Layer

- 3 mm

- Size

- 150 mm

- Abrasive Concentration

- 100%

- Thickness

- 6 mm

- Shape

- Dish

- Bonding Agent

- Resin

- Texture

- Fine

- Width

- 100 mm

- Wheel Size

- 150 mm x 100 mm x 31.75 mm

- Application

- Tool Room Grinding, Precision Grinding, Carbide Tools

- Grain Size

- Medium

- Harness

- High Hardness

Dish Diamond Rim Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID), Cheque

- Supply Ability

- 200 Pieces Per Day

- Delivery Time

- 12 TO 15 DAYS Days

- Packaging Details

- IN FOUR LAYERS. 1. IN BOX WITH BUBBLE 2. THERMOCOL SHEET 3. CARTOON BOX AND LAST 4. TRANSPARENT PVC ROLL PACKING.

- Main Domestic Market

- All India

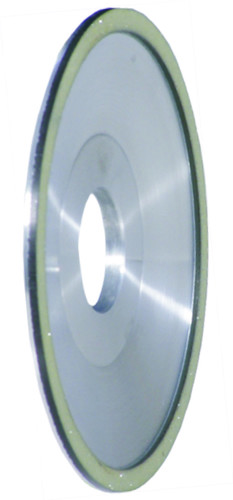

About Dish Diamond Rim

Since our inception in the year 2000, we are engaged in manufacturing, exporting and supplying a premium quality range of Dish Diamond Rim. The provided tool is manufactured under the perfect observation of our adept technocrats using pioneering techniques and finest quality raw materials that are procured from best vendors of the markets. Our provided tool is used on variety of materials for grinding purpose. In order to satisfy the several demands of our customers, the provided Dish Diamond Rim is available in diverse specifications at rock bottom prices.

Features:

-

Elevated durability

-

Precisely designed

-

Light weight

-

Fine finish

Precision Grinding for Industrial Applications

Perfect for tool rooms and carbide tool manufacturing, this Dish Diamond Rim ensures accurate and efficient grinding on a variety of hard materials including tungsten carbide, ceramics, glass, and stone. Its medium grain size and fine texture facilitate smooth, precise finishes necessary for demanding tasks.

Advanced Sintering Technology

Manufactured in India using an advanced sintering process, the wheel boasts high hardness and superior longevity. The resin bond and full diamond concentration maximize performance, making it an excellent choice for heavy-duty industrial use.

Universal Compatibility and Custom Options

Designed to fit universal grinder machines, this wheel incorporates a 150 mm diameter, 100 mm width, and a 31.75 mm hole size. If your project requires non-standard dimensions, custom sizing is available upon request to meet specific application needs.

FAQs of Dish Diamond Rim:

Q: How is the Dish Diamond Rim typically used in tool rooms or precision grinding?

A: This wheel is ideal for grinding tungsten carbide, ceramics, glass, and stone in tool rooms or for producing and maintaining carbide tools. Its precise grain and synthetic diamond abrasive deliver accurate, smooth surfaces, making it suitable for both fine finishing and material removal.Q: What is the main benefit of using an advanced sintering process for manufacturing this wheel?

A: The advanced sintering process enhances the wheels structural strength and consistency, ensuring uniform abrasive distribution. This method results in longer service life and superior performance during high-precision grinding operations.Q: When should the Dish Diamond Rim be replaced?

A: The wheel should be replaced if its working layer wears down significantly or if performance drops, though its advanced construction and full diamond concentration grant it a notably long service life compared to conventional wheels.Q: Where is this product manufactured and can it be exported?

A: Manufactured in India, the Dish Diamond Rim is available for export. It is supplied by experienced exporters, manufacturers, and suppliers, ensuring global availability with safe cardboard packaging.Q: What makes this wheel compatible with universal grinder machines?

A: The standard dimensions150 mm diameter, 100 mm width, and 31.75 mm hole sizealongside its universal design, allow the wheel to fit most grinder machines used in industrial settings.Q: How can I request a custom size for specific grinding applications?

A: To order a custom size, simply contact the manufacturer or supplier with your specifications. Customization is available to accommodate unique requirements not covered by the standard size.Q: What advantages does the synthetic diamond abrasive provide in this wheel?

A: The use of synthetic diamond at 100% abrasive concentration offers exceptional hardness and efficiency, allowing smooth, precise grinding even on very hard materials like tungsten carbide and ceramics.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Resin Bonded Diamond Wheels Category

Diamond grinding wheels

Price 800 INR / Piece

Minimum Order Quantity : 1 Piece

Size : Dia 150, W 6mm, H 31.75, D126, C100x1.5

Product Type : Diamond Dish Wheel

Abrasive : Resing Bond

Bond Type : Resin Bond

Resin Bond CBN Wheel

Price 1000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Size : 100 DIA

Product Type : INDUSTRIAL DIAMOND CUP WHEEL

Abrasive : RESIN BOND

Bond Type : ALUMINIUM

Resin Bond Diamond Radius Wheel

Minimum Order Quantity : 1 Piece

Size : Available in multiple diameters

Product Type : Resin Bond Diamond Radius Wheel

Abrasive : Synthetic Diamond

Bond Type : Resin Bond

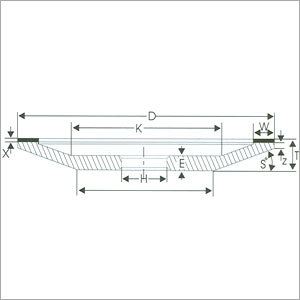

Dish Diamond in Rim

Minimum Order Quantity : 1 Piece

Size : 6 (150 mm)

Product Type : Diamond Dish Grinding Wheel

Abrasive : Diamond

Bond Type : Resin Bond

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS