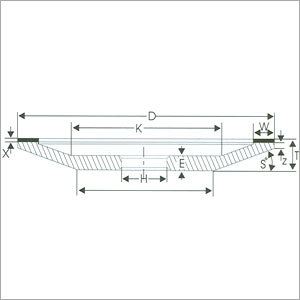

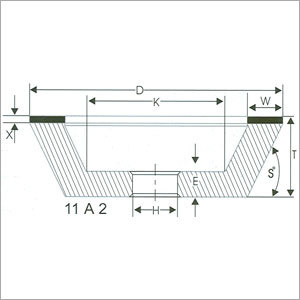

Dish Diamond in Rim

Dish Diamond in Rim Specification

- Texture

- Fine to Medium

- Abrasive

- Diamond

- Thickness

- 10 mm

- Abrasive Concentration

- 75%

- RPM

- 3600 RPM

- Depth of Working Layer

- 3 mm

- Bonding Agent

- Resin

- Abrasive Grit Size

- D91

- Grain Size

- D91 (91 micron)

- Width

- 10 mm

- Size

- 6 (150 mm)

- Harness

- Up to 82 HRC

- Wheel Size

- 150 x 10 x 32 mm

- Application

- Cutting, grinding and sharpening hard materials

- Width of Working Layer

- 10 mm

- Product Type

- Diamond Dish Grinding Wheel

- Bond Type

- Resin Bond

- Hole Size

- 32 mm

Dish Diamond in Rim Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 200 Pieces Per Day

- Delivery Time

- 12 TO 15 DAYS Days

- Packaging Details

- IN FOUR LAYERS. 1. IN BOX WITH BUBBLE 2. THERMOCOL SHEET 3. CARTOON BOX AND LAST 4. TRANSPARENT PVC ROLL PACKING.

- Main Domestic Market

- All India

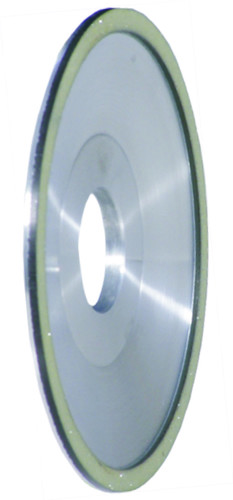

About Dish Diamond in Rim

Our continual hard work helps us in providing stellar quality Dish Diamond in Rim to our treasured clients. This tool is used for sculpturing and buffing stones. The offered tool is manufactured at our sound production unit by utilizing admirable quality raw materials and pioneering technology under the stern guidance adroit technocrats in compliance with set industry quality standards. Moreover, this Dish Diamond in Rim is available in numerous specifications as per the precise needs of the clients at market leading prices.

Features:

-

Easy installation

-

Sturdy construction

-

Application specific design

-

Ruggedness

Exceptional Performance for Hard Materials

Engineered to cut, grind, and sharpen hard materials, the Dish Diamond in Rim delivers precise results thanks to its resin bond and uniform diamond grit. The fine to medium texture enhances cutting efficiency while maintaining surface integrity, making it ideal for arduous industrial tasks.

Compatible and Versatile Usage

With a 150 x 10 x 32 mm size and 32 mm bore, this grinding wheel fits most CNC and manual grinding machines. Its adaptability ensures you can use it across multiple operations without frequent replacements, streamlining your production process.

Engineered for Longevity and Speed

Manufactured with a deep 3 mm working layer and capable of running at 3600 RPM, the wheel promises long service life when used correctly. Its smooth, metallic surface minimizes friction, reducing wear and prolonging operational lifespan.

FAQs of Dish Diamond in Rim:

Q: How should I use the Dish Diamond in Rim grinding wheel for optimal performance?

A: For optimal performance, mount the wheel securely on compatible CNC or manual grinding machines, ensuring the spindle speed does not exceed 3600 RPM. Use light to moderate pressure and apply appropriate cooling to avoid overheating, extending the wheels service life.Q: What types of materials can be effectively processed with this diamond grinding wheel?

A: This wheel is specifically designed for cutting, grinding, and sharpening hard materials up to 82 HRC, including high-speed steel, carbide, ceramics, and similar substrates requiring precision and durability.Q: When should I replace the Dish Diamond in Rim grinding wheel?

A: Replace the wheel when you notice significant reduction in cutting efficiency, uneven wear of the working layer, or if the thickness of the diamond segment reduces significantly, ensuring safe and precise operations.Q: Where can I use this product?

A: The Dish Diamond in Rim wheel is suitable for use in industrial workshops, manufacturing plants, and tool rooms equipped with CNC or manual grinding machines, especially in environments that require high-precision tool fabrication and sharpening.Q: What is the process for mounting and using this grinding wheel?

A: Ensure the machine is switched off and secured. Mount the wheel onto a clean spindle, verifying that the 32 mm hole fits snugly. Tighten the mounting flange evenly, conduct a trial run at a reduced speed, then operate at the designated maximum speed of 35 m/s (3600 RPM).Q: What are the benefits of using this product for industrial grinding?

A: Key benefits include high precision, consistent surface finish, extended service life, and versatility in handling various hard materials. The diamond abrasive ensures efficient material removal and minimal downtime for wheel changes.Q: What safety precautions should I observe while using this grinding wheel?

A: Always wear appropriate personal protective equipment such as safety goggles, gloves, and face shields. Ensure correct mounting, avoid exceeding the specified RPM, and use coolant as required to prevent thermal damage to both the wheel and the workpiece.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Resin Bonded Diamond Wheels Category

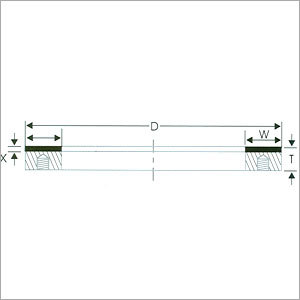

Diamond grinding wheels

Minimum Order Quantity : 1 Piece

Bond Type : Resin Bond

Product Type : Diamond Dish Wheel

Application : Carbite Grinding

Size : Dia 150, W 6mm, H 31.75, D126, C100x1.5

Width : 6mm Millimeter (mm)

Cylinder Diamond in Rim

Minimum Order Quantity : 1 Piece

Bond Type : Metal bonded

Product Type : Cylinder Diamond in Rim

Application : Precision grinding, cutting, machining, and polishing of hard materials

Size : Standard and custom sizes available

Width : Customizable as per requirement

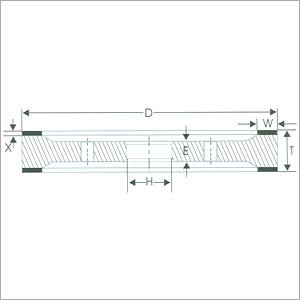

Double Cup Diamond in Rim with Bolt Holes

Minimum Order Quantity : 1 Piece

Bond Type : Metal Bond

Product Type : Double Cup Diamond Wheel In Rim with Bolt Holes

Application : Concrete surface grinding, stone polishing, surface leveling

Size : Available in 100 mm, 125 mm, 180 mm diameters

Width : Segment Width: 5 mm (may vary depending on manufacturer specifications)

Taper Cup Diamond in Rims

Minimum Order Quantity : 1 Piece

Bond Type : Metal Bond

Product Type : Taper Cup Diamond Wheel (in Rims)

Application : Grinding, precision tool sharpening, carbide, glass, ceramics

Size : Available in various standard and custom sizes

Width : Customize as per application

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS