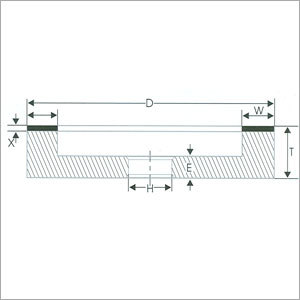

Plain Cup Diamond in Rim

Plain Cup Diamond in Rim Specification

- Abrasive

- Diamond

- Thickness

- 5 mm to 30 mm

- Width of Working Layer

- 5 mm to 15 mm

- Bond Type

- Resin Bond / Metal Bond

- Product Type

- Plain Cup Diamond in Rim

- Application

- Grinding, Surface Finishing, Precision Engineering

- Hole Size

- 20 mm to 32 mm

- Size

- Customizable

- Bonding Agent

- Resin or Metal

- Width

- 10 mm to 50 mm

- Harness

- High

- Wheel Size

- 75 mm to 200 mm diameter

- Shape

- Cup

- Abrasive Concentration

- Standard & Customized

- Abrasive Grit Size

- Available from coarse to fine grits

- Depth of Working Layer

- 3 mm to 8 mm

- Texture

- Smooth

- Grain Size

- D46 to D151

Plain Cup Diamond in Rim Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 200 Pieces Per Day

- Delivery Time

- 12 TO 15 DAYS Days

- Packaging Details

- IN FOUR LAYERS. 1. IN BOX WITH BUBBLE 2. THERMOCOL SHEET 3. CARTOON BOX AND LAST 4. TRANSPARENT PVC ROLL PACKING.

- Main Domestic Market

- All India

About Plain Cup Diamond in Rim

Having an aim to introduce the finest quality products, we are engaged in manufacturing, exporting and supplying a quality assortment of Plain Cup Diamond in Rim. The provided tool is precisely manufactured by utilizing contemporary technology and top grade raw materials that are sourced from the best vendors of the market. Available in various specifications as per clients needs, this tool is used in carbide single point turning tools for off-hand grinding. Moreover, our prestigious clients can purchase this Plain Cup Diamond in Rim at rock bottom prices.

Features:

-

Stable dimension

-

Light weight

-

Precisely designed

-

Abrasion resistance

Versatile Precision Across Hard Materials

Our Plain Cup Diamond in Rim wheels are engineered to deliver outstanding grinding, finishing, and shaping results on tough substrates such as tungsten carbide, ceramics, glass, stone, and hard metals. Whether working in dry or wet environments, their exceptional durability and precise manufacturing tolerance of 0.2 mm ensure accuracy and consistency in high-demand applications.

Customizable for Every Requirement

A wide range of customizable options is available, including wheel dimensions, bond type (resin or metal), grit sizes, and abrasive concentrations, allowing users to adapt the tool for coarse or fine finishes. With a minimum order quantity of just one piece and the ability to cater to specific engineering needs, these wheels add value to both small-scale and large-scale operations.

FAQs of Plain Cup Diamond in Rim:

Q: How can I select the right grit size and bond type for my specific application?

A: The appropriate grit size (from D46 to D151) and bond type (resin or metal) should be chosen based on the material being processed and the desired finish. Coarser grits are ideal for rapid material removal, while finer grits are best for achieving a smoother surface. Resin bonds offer flexibility for delicate surfaces, whereas metal bonds are optimal for aggressive grinding tasks.Q: What materials can the Plain Cup Diamond in Rim safely grind or finish?

A: This cup wheel is compatible with a variety of hard materials, including tungsten carbide, ceramics, glass, stone, and hard metals. Its robust diamond abrasive ensures consistent performance and longevity across all supported substrates.Q: When should I use a cup diamond wheel with a resin bond versus a metal bond?

A: Resin-bonded wheels are preferable for precision surface finishing and grinding where a gentle touch and minimal thermal influence are needed. Metal-bonded wheels, on the other hand, are suitable for tasks that require enhanced durability and higher grinding efficiency, especially on harder workpieces.Q: Where is this product manufactured and can it be exported internationally?

A: The Plain Cup Diamond in Rim is manufactured in India by reputable exporters, manufacturers, and suppliers. International export options are available, making the product accessible to a global clientele.Q: What benefits does the customizable core material (steel or aluminum) offer?

A: Steel cores provide robustness and stability, making them ideal for heavy-duty grinding. Aluminum cores, being lighter, are suitable for applications requiring reduced tool weight and easier handling without sacrificing precision.Q: How can I order a custom wheel and what is the minimum order quantity?

A: Customization is available for all specifications, including size, bond, abrasive type, and grit concentration. Orders can be placed for quantities as low as one piece, allowing both individual and bulk buyers to tailor tools to their unique requirements.Q: What is the process to maintain optimal service life for this grinding wheel?

A: Proper mounting, adherence to recommended operating speeds, regular wheel dressing, and using the wheel within its designed dry or wet operating environment will extend service life and ensure consistent results during use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Resin Bonded Diamond Wheels Category

Diamond Radius Wheel

Price 1000 INR / Piece

Minimum Order Quantity : 1 Piece

Width : 10 mm

Harness : Diamond Hardness

Shape : Radius

Abrasive Concentration : 75%

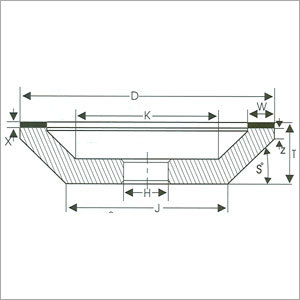

Taper Cup Diamond in Rim

Minimum Order Quantity : 1 Piece

Width : Customizable as per requirement

Harness : High Hardness

Shape : Cup (Tapered)

Abrasive Concentration : Customized

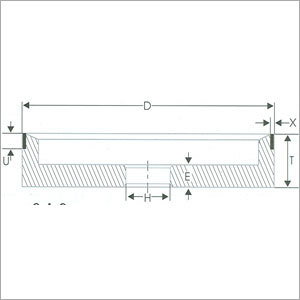

Plain Cup Diamond in Corner-diamond wheel

Minimum Order Quantity : 1 Piece

Width : Customizable

Harness : High hardness (suitable for hard material processing)

Shape : Cup (with corner edge)

Abrasive Concentration : 75%, 100%, or as specified

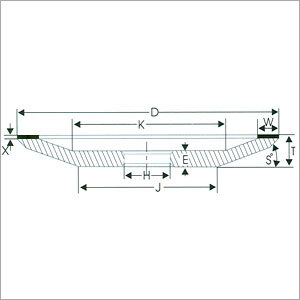

Rims Dish Diamonds

Price 900 INR / Piece

Minimum Order Quantity : 1 Piece

Width : 1MM TO 1000MM Millimeter (mm)

Harness : Diamond below 45 hrc/ CBN 45 hrc up

Shape : ROUND

Abrasive Concentration : C50/C75/C100

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS