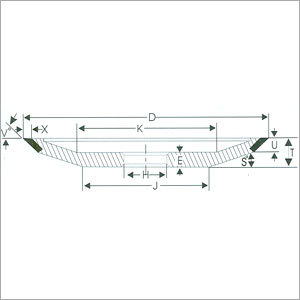

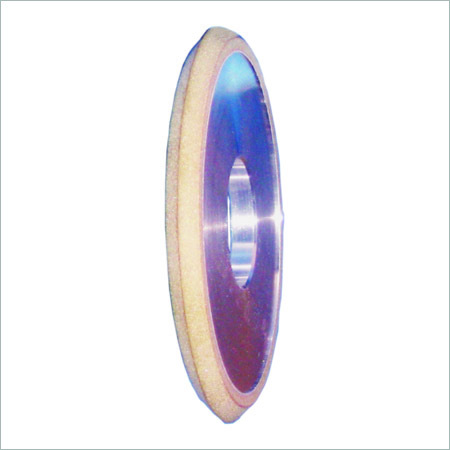

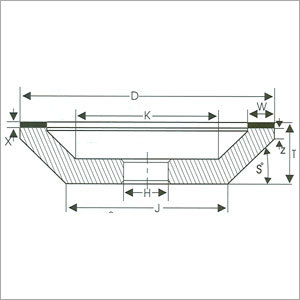

Dish Diamond in Corner

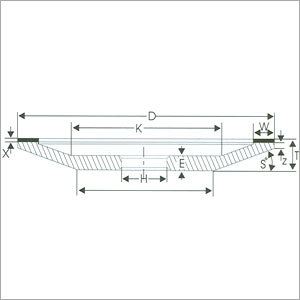

Dish Diamond in Corner Specification

- Abrasive

- Industrial Diamond

- Product Type

- Dish Diamond in Corner Wheel

- Shape

- Dish (in Corner)

- Thickness

- 5 mm

- Hole Size

- 31.75 mm (1.25 inch)

- Grain Size

- Fine

- Abrasive Grit Size

- D46 (approx.)

- Harness

- Super Hard

- Width of Working Layer

- 2 mm

- Bonding Agent

- Resin

- Width

- 5 mm

- Wheel Size

- 100 mm x 5 mm

- Bond Type

- Resin Bonded

- Application

- Grinding, Precise Edge Polishing, Tool Sharpening

- Abrasive Concentration

- Standard

- Size

- 4 inch

- RPM

- Max 4500 RPM

- Texture

- Smooth

- Depth of Working Layer

- 3 mm

Dish Diamond in Corner Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 200 Pieces Per Day

- Delivery Time

- 12 TO 15 DAYS Days

- Packaging Details

- IN FOUR LAYERS. 1. IN BOX WITH BUBBLE 2. THERMOCOL SHEET 3. CARTOON BOX AND LAST 4. TRANSPARENT PVC ROLL PACKING.

- Main Export Market(s)

- Asia, North America

- Main Domestic Market

- All India

About Dish Diamond in Corner

With an aim to be an innovative and bankable firm, we are engaged in offering Dish Diamond in Corner. The offered tool is precisely manufactured at our sound production unit using the finest grade raw materials and state-of-the-art methodologies under the supervision of deft technocrats in compliance with set industry norms. Available in various specifications, this tool is highly admired by our clients owing to its smooth finish and elevated durability. Moreover, our offered Dish Diamond in Corner is available for our clients at industry leading prices.

Features:

-

Dimensional accuracy

-

Smooth surface finish

-

Easy installation

-

Precisely designed

Precision Engineering for Superior Performance

Constructed using high-quality industrial diamond and resin bonding, the Dish Diamond Wheel delivers exceptional durability and a consistently smooth grind. Its fine abrasive grain and unique dish shape are tailored for delicate operations, enabling users to achieve optimal edge sharpness and polish on a variety of tools and components.

Ideal Applications and Versatile Use

Perfect for applications such as grinding, edge polishing, and tool sharpening, this wheel excels in settings that demand precision and resilience. The dish-in-corner design is particularly effective for accessing tight spots, making it indispensable for fine finishing tasks across several industrial and workshop environments.

FAQs of Dish Diamond in Corner:

Q: How does the dish-in-corner design enhance grinding and polishing tasks?

A: The dish-in-corner shape allows for greater control and precision, especially when working in tight spaces or on detailed components. This design ensures consistent contact with the material, enabling accurate edge polishing and effective tool sharpening.Q: What materials can be processed using this Dish Diamond Wheel?

A: The wheel is engineered for use on hard materials that require fine finishing, such as carbide, ceramics, and other industrial materials. Its super-hard, diamond-based abrasive ensures efficient results on demanding surfaces.Q: When should this diamond wheel be replaced?

A: You should consider replacing the wheel when the working layer (3 mm deep, 2 mm wide) is worn down or if you notice diminished cutting or polishing performance, ensuring continued precision and safety.Q: Where is this product manufactured and can it be exported internationally?

A: This Dish Diamond Wheel is produced in India and is available for export. As an experienced manufacturer and supplier, global shipping can be arranged to meet your business requirements.Q: What is the recommended process for mounting and operating the wheel?

A: Carefully mount the wheel using the 31.75 mm (1.25 inch) bore onto compatible machinery. Always ensure proper alignment and secure attachment before use, and operate below the maximum speed limit of 4500 RPM for safety and efficiency.Q: How is the benefit of the resin bonding and diamond abrasive technology realized in practice?

A: Resin bonding in combination with industrial diamond provides optimal balance between cutting speed, durability, and heat resistance. This results in a longer-lasting wheel, reduced need for frequent replacement, and consistently fine, smooth finishes during operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Resin Bonded Diamond Wheels Category

Diamond Angle Wheel

Price 2000 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : INDUSTRIAL DIAMOND WHEEL

Bonding Agent : DIAMOND/CBN

Application : carbide grinding

Bond Type : resin bond

Diamond grinding wheels

Price 800 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Diamond Dish Wheel

Bonding Agent : Resing Bond

Application : Carbite Grinding

Bond Type : Resin Bond

Taper Cup Diamond in Rim

Minimum Order Quantity : 1 Piece

Product Type : Taper Cup Diamond Wheel

Bonding Agent : Metal Bonding

Application : Grinding, Cutting, Precision Tooling

Bond Type : Metal Bond

Dish Diamond in Rim

Minimum Order Quantity : 1 Piece

Product Type : Diamond Dish Grinding Wheel

Bonding Agent : Resin

Application : Cutting, grinding and sharpening hard materials

Bond Type : Resin Bond

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS